Garrattfan's Modelrailroading Pages

NS 5500 class

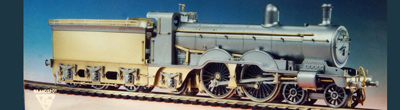

Project NS5555

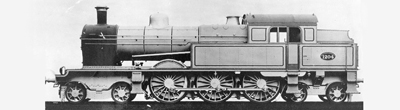

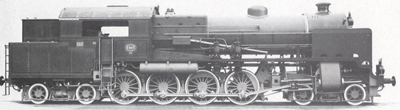

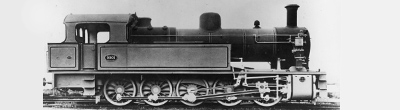

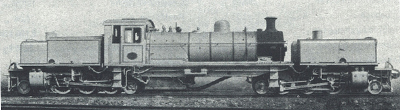

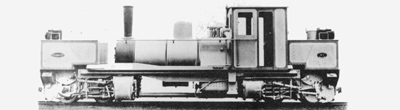

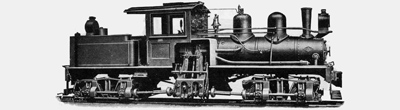

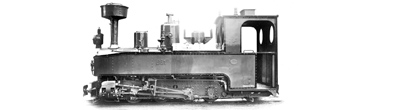

The prototypeBuilt from 1898 till 1905 for the HSM (Hollandsche Spoorwegmaatschappij) this series was an attempt to standardize on locomotive types. With 55 built the 5500 was a relatively numerous class (for Dutch circumstances). Their domain was to be found in the light but relatively fast passenger service on dead end lines. With their 1800 mm drivers they attained a speed of 90 km/h. The success of this design may not only be read in their numbers but also in in their conduit state: the first loco to leave active service was 5540 due to war damage in May 1940. After the war only 10 examples were more or less fit for use. Although in all 39 were restored to operational condition their days were numbered. The last one was set aside in 1954. None of them has been preserved.

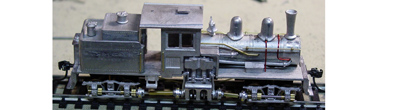

Atlantic or notIt is a perpetual discussion whether a 4-4-2 tank engine is an Atlantic or not. An Atlantic is generally understood as a 4-4-2 tender engine. But this name originates from the US were in 1894 a batch of 4-4-2's was delivered to the Atlantic Coast Line. Although the type had been produced before that date this batch is the namesake for the Atlantic type. The modelThe series 5500 is available in HO scale by DJH. I bought this white metal kit in April 2009 at a price of only 75 euro. Normal prices hover around 230 euro. I had seen photos of other work of the same hobbyist on the internet and knew not to expect too much. I was well aware that I was in for a decent restoration job. Well, I wasn't going to be disappointed ;-)

|

|

The main components as I found them in the well worn DJH box. The warped footplate... |

|

...is was sprayed with an unknown peculiar silvery substance. I hope it is paint and that it will not resist thinner. Otherwise I'm in for a thorough glass fiber pen scrubbing job! |

The other buffer beam shows serious damage. I wonder what happened to this loco. It looks as if it was used for a Saturn V pre-tryout and vertically returned from orbit. |

The most serious job seemed to be on the main frame. Ahead of the drivers everything was gone. The front bogie was not in the box and the frame is warped and cut off at or broken the height of the second running axle of the bogie. Later I received the construction manual via a friend (txs Hans) and it turned out that things were not as bad as they appeared. The mainframe is supposed to end like this. Taking it apart and a good thorough rebuild will do the job. The missing bogie needed replacement though but as twitch a fate it incidentally turned up at the previous owner and he was so kind to send it to me. It is however of the ususal crude white metal contruction so typical of DJH's Dutch models. So I might consider building a brass bogie myself. |

|

The superstructure seems to be in a reasonable state. I could find no serious damage. So far for the Saturn V conspiracy theory. First I'll send them bathing in thinner to remove the paint for closer inspection. |

|

Disassembly, always a tedious job on the soft white metal kits of DJH, proved easy. Exerting little pressure with my fingers was sufficient to hear joins crack. A little more pressure and the whole thing came apart in less than two minutes. |

|

The components of the superstructure after a few hours in thinner. The good news is: the paint came off as well as the major part of the glue. The bad news is: the silvery coat is resistant to thinner. Moreover, the glue that was covered with this coat is also resistant and the respective applied parts stayed in place. That is going to cost me quite some time to get this right. |

|

The unordered collection of additional parts. I will have to spend quite some time completing missing parts or replacing damaged parts. For some parts incompleteness is hardly a problem, since I would have replaced them anyway, like the headlights which I will buy from Philotrain. Small stuff like stanchions are readily available in the after market. The air pump and the drivers cab's steps for instance may prove more of a problem |

|

Though not officially a project I tend to work a little every now and then on this loco when I'm fed up with the NGG16 project. I intend to use the 5555 as a guinea pig for compensation beams as recommended by Iain Rice (Locomotive Chassis Construction in 4 mm) and Mike Sharman (Flexichas, A way to build a fully compensated locomotive chassis). In the mean time less noble jobs awaited me.The frame assembly wouldn't move for an inch. I took it apart. The motor was seriously contaminated with metal debris. With a lot of patience I removed the debris from the motor and after an hour or so I had retrieved a running motor from the wreckage. |

|

The frame was seriously warped an dented |

|

The frame didn't even come close to lying flat on a sheet of glass. I took the lot apart and sent it swimming in thinner for a day or so. |

|

|

|

| At this stage the original owner contacted me: He had found the missing bogie and roof. Next day they arrived by mail. | |

|

|

.jpg)

Sign my

GuestBook