Garrattfan's Modelrailroading Pages

NS 3900 class

Inventory

The model itself |

|

DJH produce this loco in kit form. To date (2024) there is no mass produced RTR model available, contrary to the 6300 and 3700 classes of which an excellent model has been produced by Artitec. I stumbled upon a built example of the DJH kit on a trade show in Houten in December 2023. Asking price was €105. After some haggling we agreed on €80 and we were both happy. |

|

|

|

It was glaringly obvious that it was in bad shape, I quickly assessed the model and concluded:

By the time I had decided it was feasible to rebuild this model I was approached by the stand holder. After some haggling we agreed on €80.

Once home I made a few official portraits: |

|

|

|

|

|

As you can see there really noting straight on this model |

|

Assessment |

|

It is easy to discredit the previous owner / builder. But no. I am convinced this model was lovingly built by a modeller but one with very limited experience. I have an image in my mind of a 15 year old youngster who had built only plastic kits before. He wanted to have a real 3900 of his own on his layout. Having spent all his saving he desperately tried to create a beautiful model out of this kit. Oh boy, must he have been disappointed. I don't think it ever ran. It went into store, never to come out again until the whole hobby stuff was sold in later years. If this (young?) aspiring builder ever reads these lines: I hope you did not loose your appetite for building locomotives. Follow this build and others I have built. Live and learn and follow your dream again. Contact me if you want to. |

|

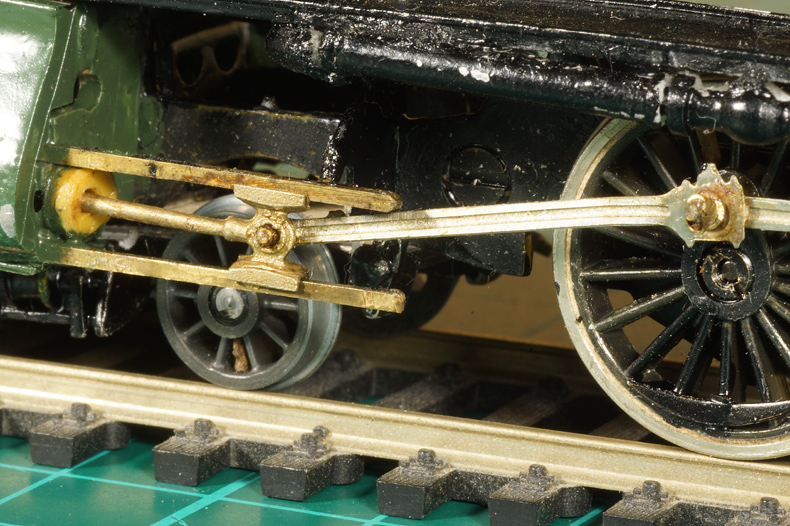

The cross head out of its guides is not the problem. Its just the general condition: nothing is straight, nothing sits really well, noting is deburred or filed to fit. The bolt through the crosshead is secured with a glued O-ring. |

|

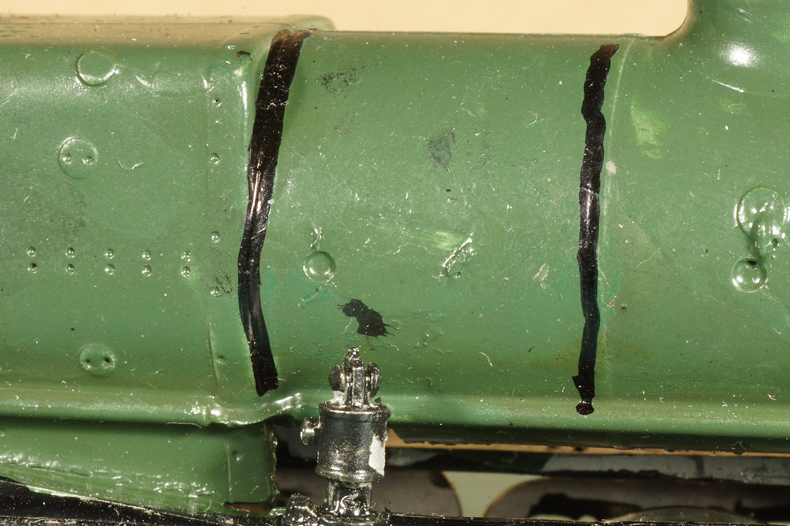

The paintwork is awful. No sign of any primer. Lining is done by hand. Residues of glue are all over the place and painted over. Note the gap between the driver's cab and the firebox. |

|

Again boiler bands were painted by hand, and not a very steady hand at that. |

|

No visible attempt was made to make parts fit well. Parts were simple pushed into place straight from the box. Burrs were left as is. |

|

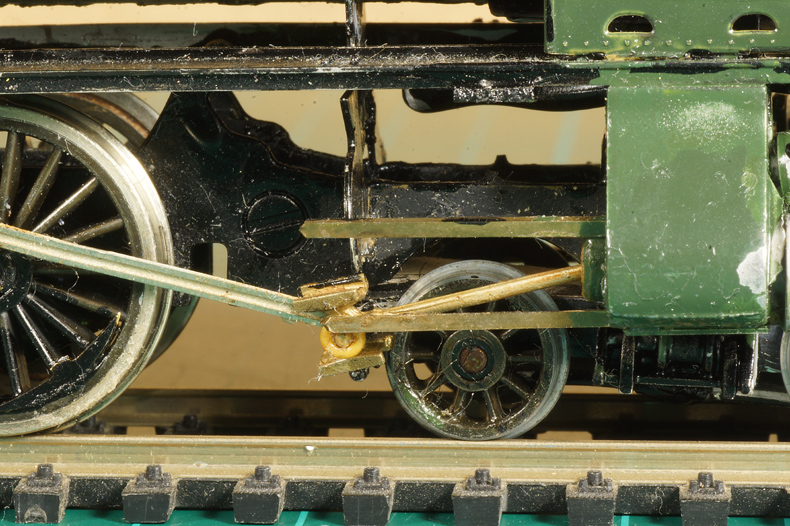

There was an industrial drive of unknown origin mounted inside. It came nowhere near the desired measures. Look how much the distances between the axles differ from the axleboxes on the tender side. |

|

|

|

The tender top is not even close to a any sort of fit. |

|

But the good news is: there nothing major wrong with this model. All major components are there as far I can judge now in pretty good condition. |

|

Disassembly |

|

| To get the full view of what I had in hands it was necessary to disassemble the model and assess each and every part individually. I was lucky in that the builder had followed DJH's awkward lead that the model could also be glued with superglue. Of course it can! You can also drive a screw into wood with a hammer. Believe me, if you do not have the skill, or the wish to acquire it, to solder this model then you'd better stay away from it. But now this was to my advantage as superglued kits are usually very easy to disassemble by dunking it is acetone. | |

But before I could do that, I had to remove the drive mechanism. The parts of the tender came apart without much persuasive force. |

|

After cleaning with cellulose thinner no serious deficiencies were found. |

|

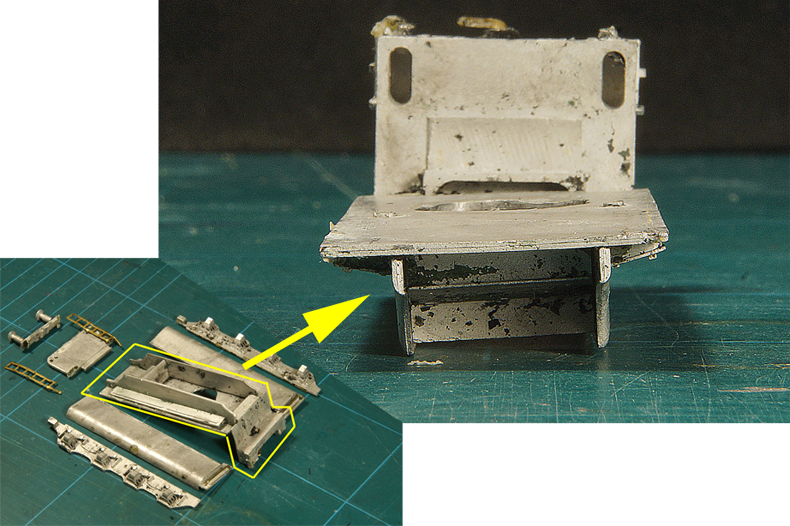

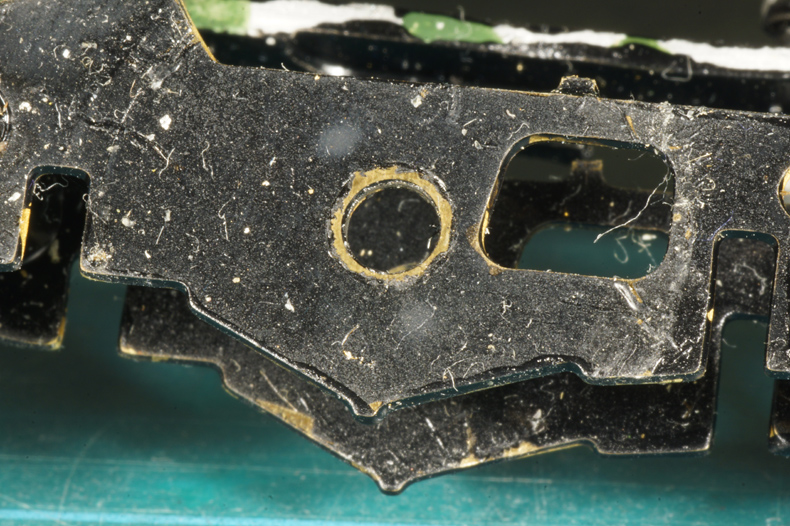

This is the tender upside down, looking from the rear to the front. This photo says without words what was wrong with this model. |

|

Then I put the parts in a jar of acetone. Within an hour the whole tender fell in pieces and the residues of the paint came off. In hindsight I could have skipped the soaking in thinner as the aceton takes care of that as well. |

|

A fully cleaned tender side. There some residual discolourations from the superglue but that will be taken care of by fresh coat of paint. The deep scratch mark on the left can be fixed with JB Weld. |

|

| Then I set to work at the locomotive. | |

I carefully removed the wheels. |

|

|

|

|

|

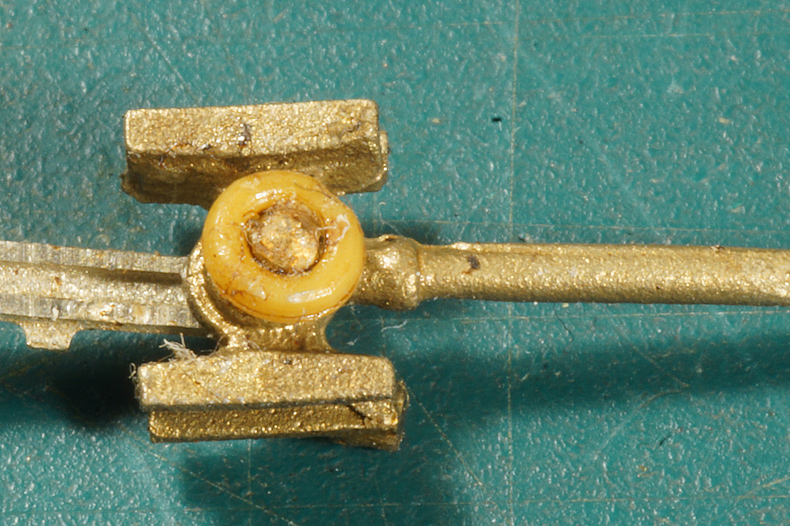

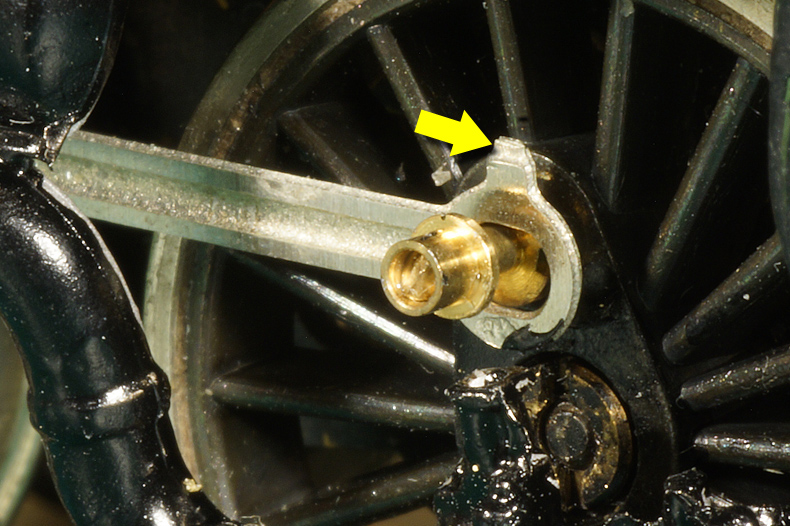

A detailed look at the crosshead and its funny way of securing it. I simply cannot imagine that the builder had not clue what a bolt and nut are for (or he may have lost the nut, hmmm). |

|

On the other side the cross head bolt was not secured at all (or the O-ring must have departed). I found another O-ring at the back of the left cylinder. It completely baffles me why it was there. |

|

The cylinder block is nearly falling apart by itself. |

|

By now it had become apparent that the builder had no inkling what all the shiny thingies were for. The crankpin bush glued wrong side in at the very end of the crankpin. Impossible this locomotive's wheels ever turned one full turn! Note that the rod was not de-cusped. Not even the etch tab on the top end was filed away (arrow). |

|

And (probably) to make it all run the drive rod was bent. But there is no way the unshortened crankpin could have passed the drive rod. |

|

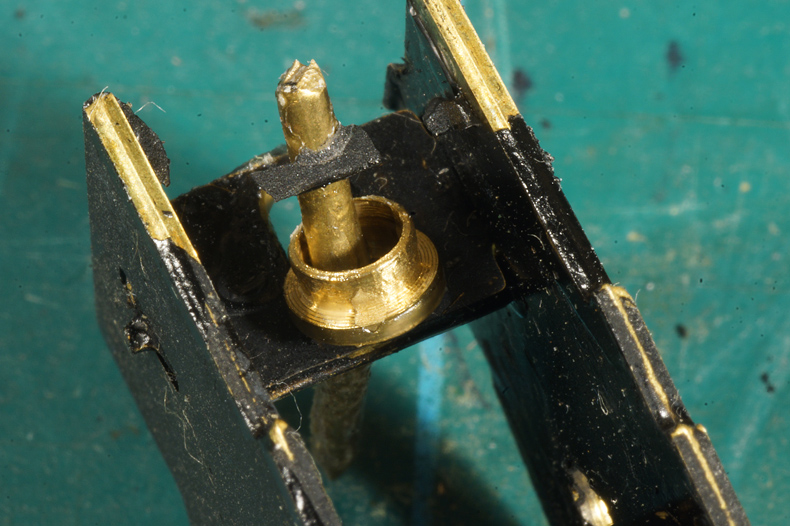

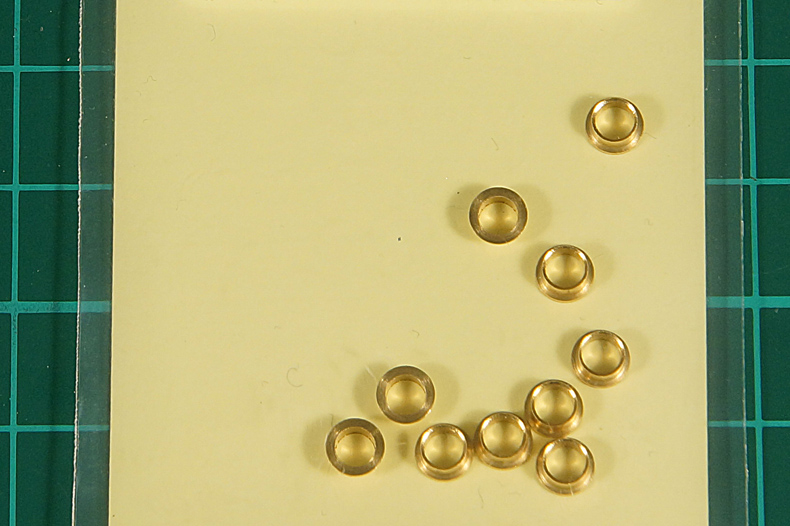

The frames we not even glued but simply screwed together. They were also built without mounting the appropriate axle bushes. The axles rattled about loosely in the frames. Again there was no trace of filing the etching cusps. In a way I am grateful for that. A builder with this level of proficiency would have destroyed the frames if he had tried any sort of filing. I could not find any of the axle bushes in the box. |

|

The whole frame after it was detached form the locomotive body. Seeing the whole level of accuracy there was no merit in trying to preserve the frame as it was. No way it would be anywhere near square. |

|

Oh, look, there is one of the axle bushes!! In use as a means of keeping the tender coupling in check! |

Oh dear, the smokebox spacer was folded inside out. This means the frames were spread about a whole millimetre further apart than intended. This justifies my decision to take the frames apart and rebuild it. |

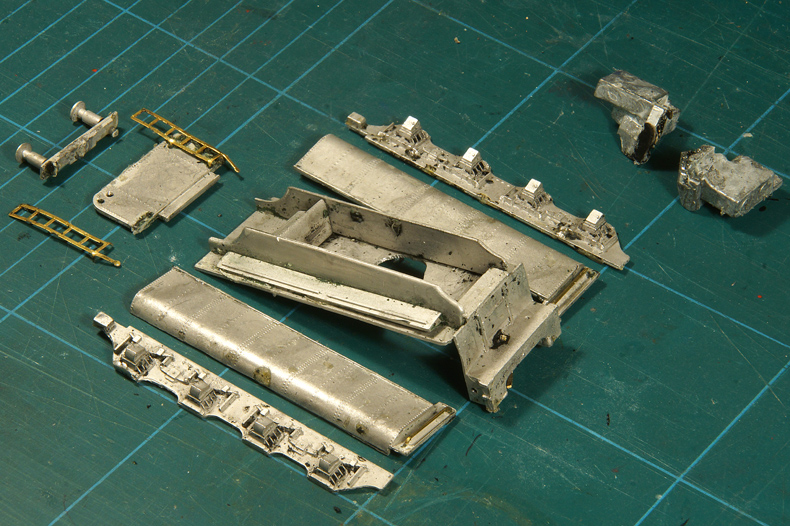

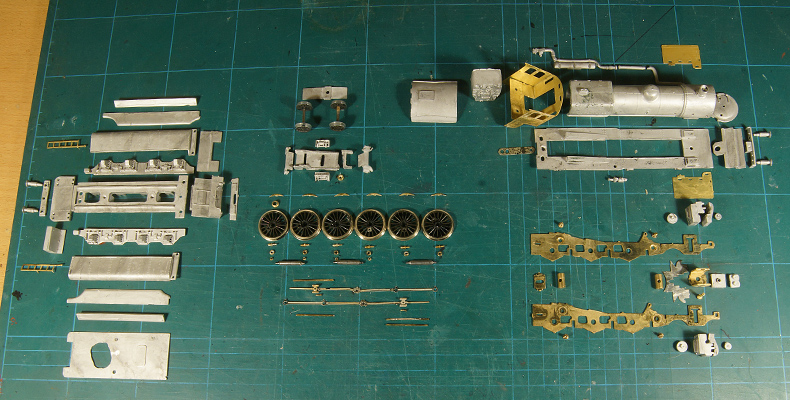

After a painstaking and diligent disassembly I got to this. |

|

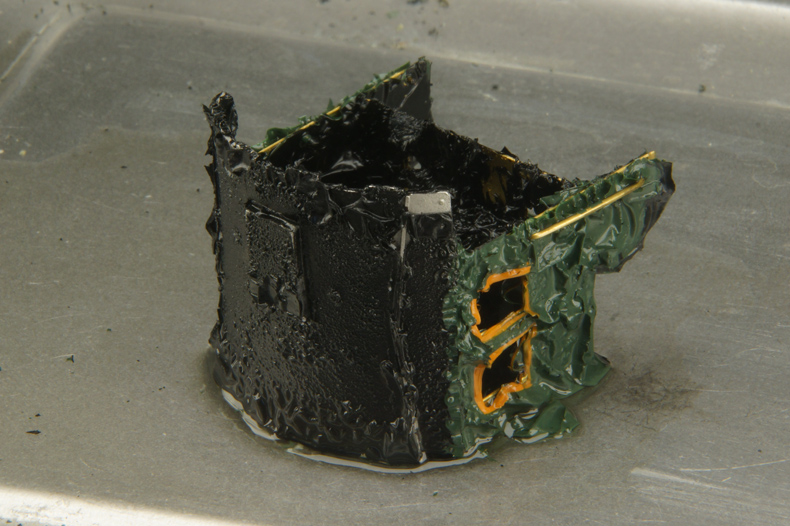

Now it was time to call in the cavalry. First a bath in cellulose thinner to dislodge the paint and then a few hours in acetone to dissolve the superglue. This is what cellulose thinner does to the paint work. |

|

All parts cleaned and layed out. |

|

What was missing? Well, apart from the motor and gearbox, nothing major but yes there are quite a few small parts absent

All in all, not bad, nothing that cannot be replaced. |

|

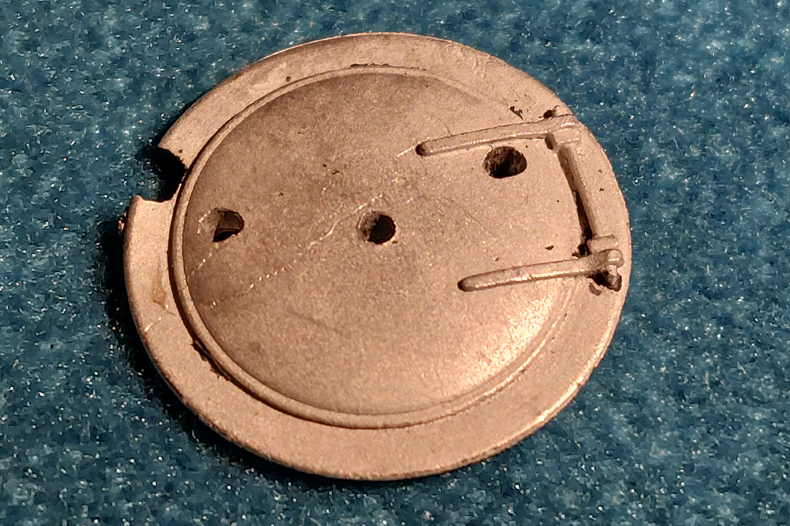

This was a bit of riddle. What is this hole in the smokebox door? Was that damaged? If so, it would be a lot of work to repair it. |

|

|

|

| It looks like the smokebox door was made this way. I have no idea why. But than again: nothing major. I will repair it | |

Additional detail parts |

|

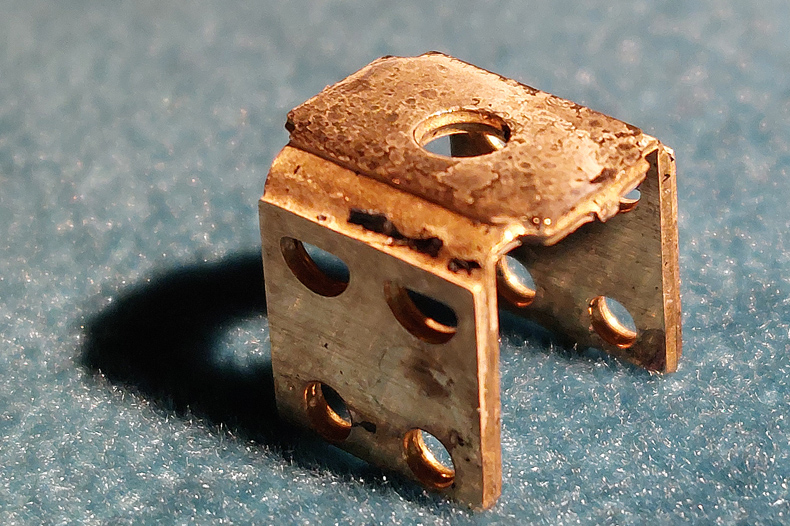

| Although DJH kit are good there are some parts I always replace. Small parts with intricate details are usually better in brass than in white metal. I also replace them because brass parts are more robust. | |

Tender wheels, Alan Gibson |

|

| 1/8 in axle bushes for the locomotive driving axles, Alan Gibson | |

|

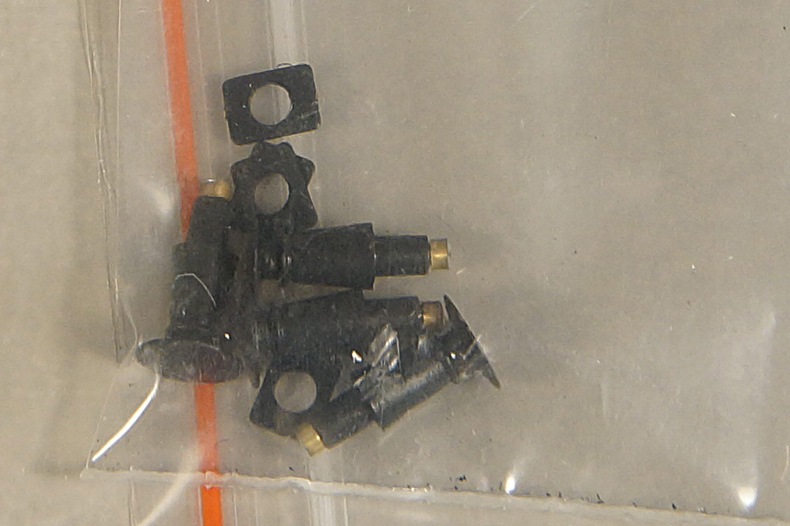

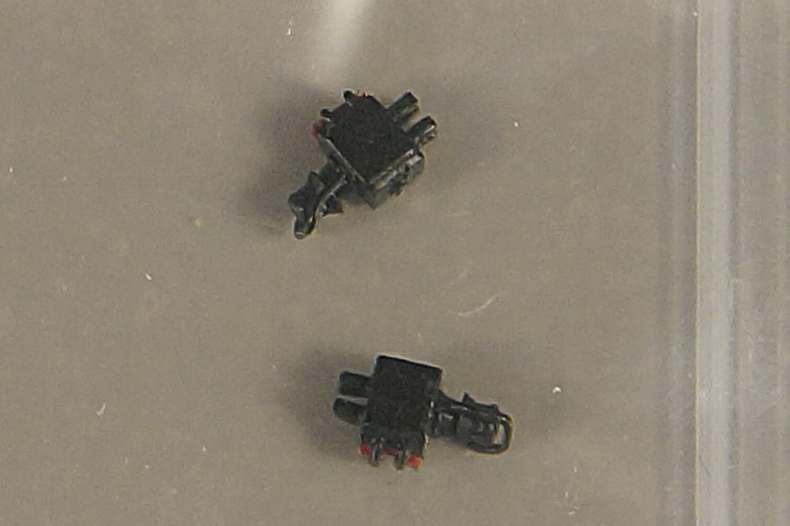

Airhoses, Philotrain |

|

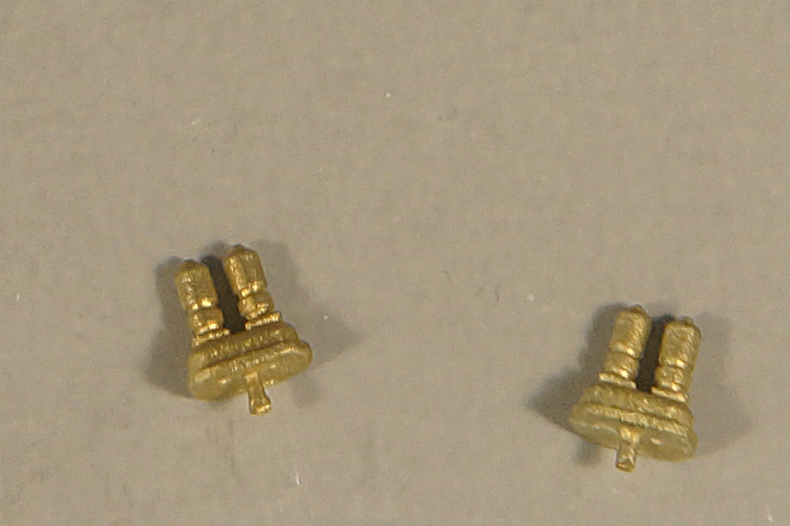

Headlamp holders, Philotrain |

|

Safety valves, Philotrain |

|

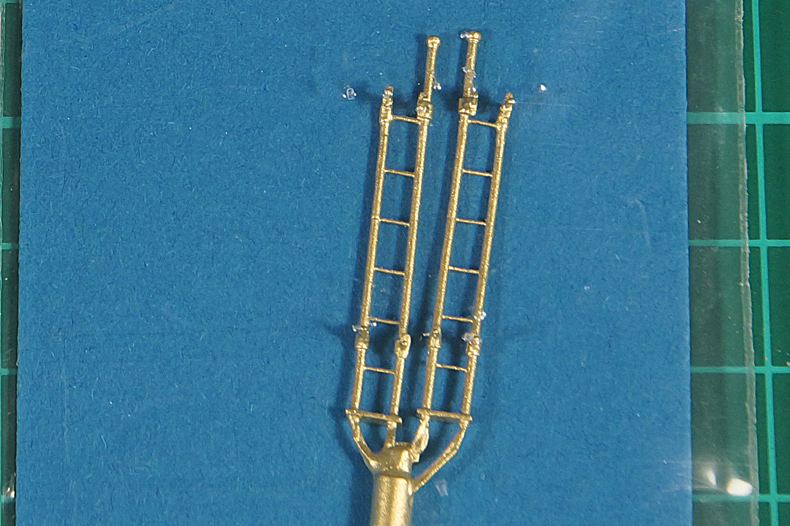

Ladders, Philotrain |

|

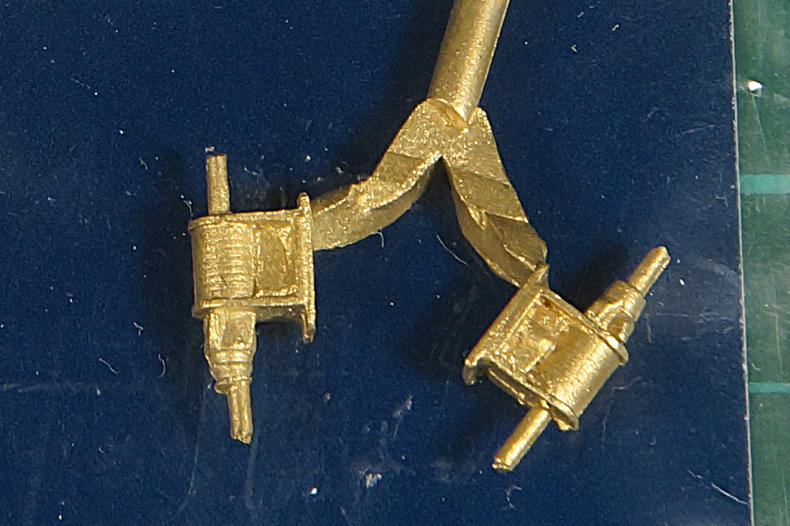

Bogie brake cylinders, Philotrain |

|

Air pump, Philotrain |

|

Sprung buffers, Philotrain |

|

Tail lamps, Philotrain |

|

Chimney, Philotrain |

|

Sprung couplers, Philotrain |

|

Smokebox handwheels, Philotrain |

| On order are the following items | |

|

|

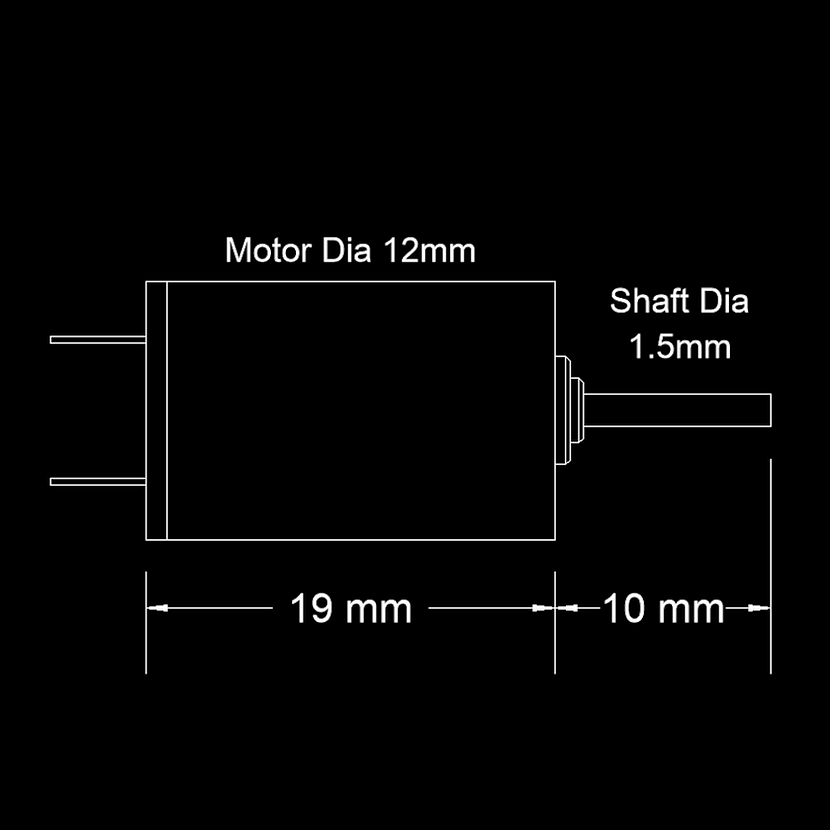

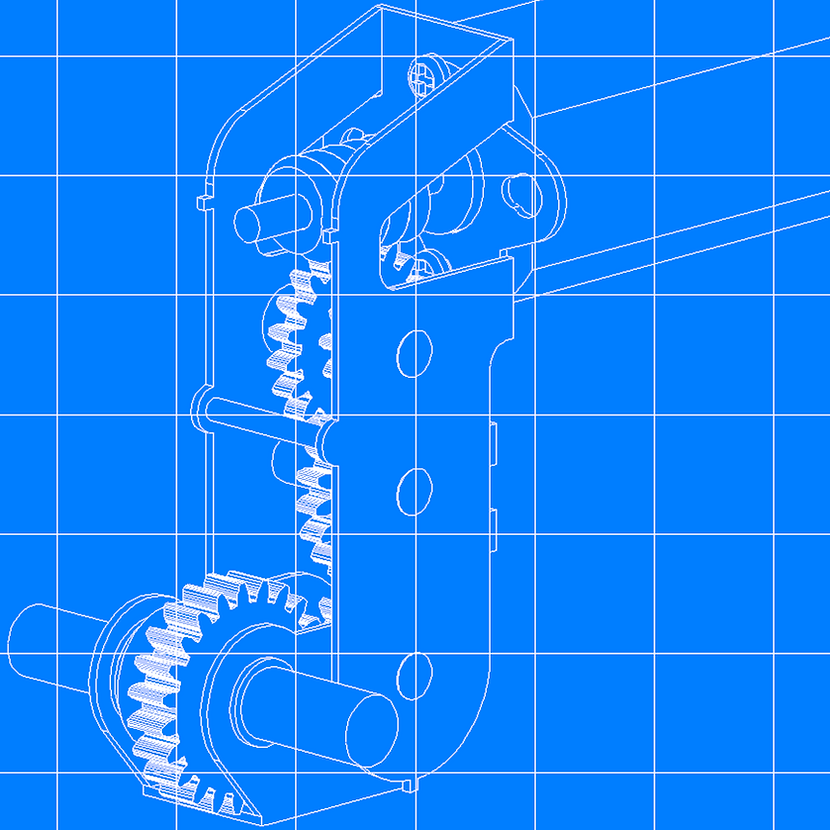

Motor, High Level Kits, 1219C and HiFlier Plus gearbox. I ordered two of each, as I want my 3900s to be able run as a double header, so they need to have approximately the same speed. |

|

Sign my

GuestBook