Garrattfan's Modelrailroading Pages

SAR GMA/M (rebuild)

Inventory of the kit

Unpacking and first look |

|

|

|

| The loco was well packed by the seller. The original DJH box was correctly advertised as "damaged". It had been thoughtfully lengthened to house the completed model in its box. Well, I could see the point of that. | |

It came out of the box in a flurry of loose parts. |

|

|

After some arranging of parts relative to their intended location I concluded nothing serious was missing. |

|

|

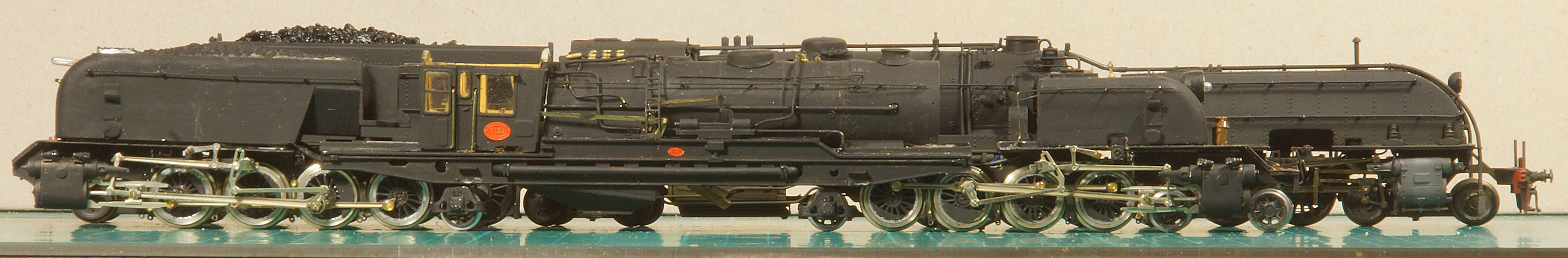

Three quarter front view on the right hand side. Click on the photo to enlarge |

|

|

Three quarter rear view on the left side. Click on the photo to enlarge |

|

General assessment |

|

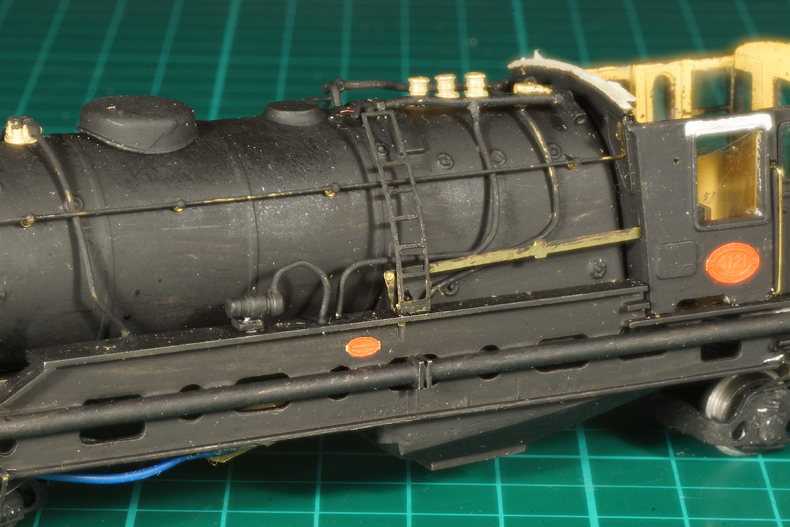

Every detail oozes that this loco was built with love. There is glaring evidence however that the builder was also not very experienced at building metal kits.

Taking a look at the way this loco was built I wonder it ever ran satisfyingly. |

|

The lighting was done with a grain of wheat, probably the best available at the time. The lamp itself has come off and I do not regret that as it was a rather crude plastic affair with little resemblance of the real thing. |

|

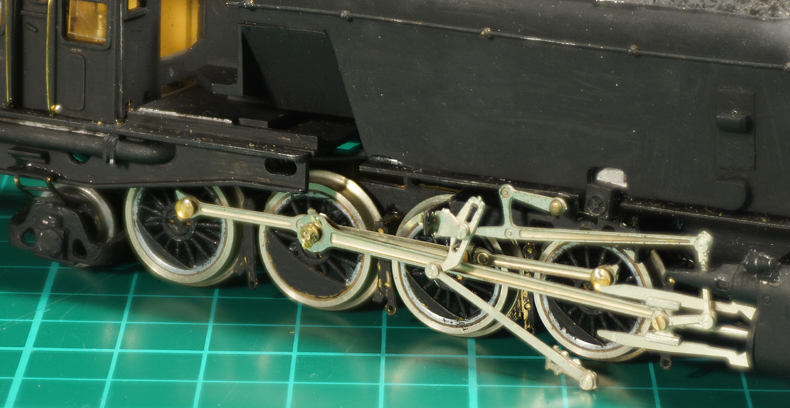

Unsurprisingly two of the four valve gear sets had come loose. |

|

|

|

|

|

|

|

|

|

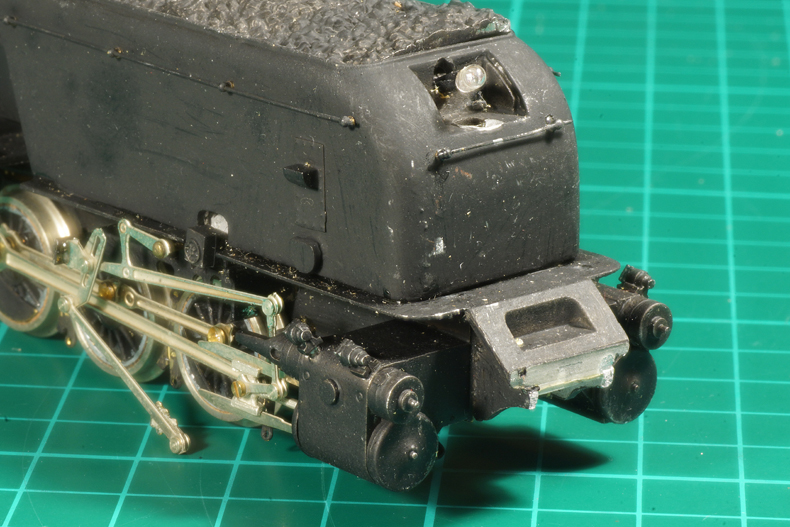

On the front tank the ugly headlight was still in place, but it would soon find its fate in the bin. |

|

|

|

|

|

|

|

The front skirt cum buffer beam (but SAR locomotives did not have buffers, so wa do ya callem?) has broken off, but it is among the flurry of loose parts. |

|

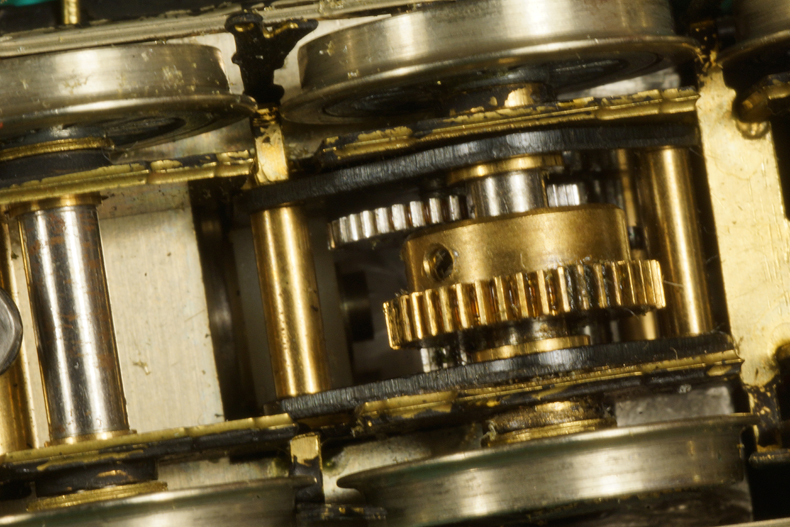

Taking a look underneath. Where builders tend to do their best on the superstructure the underside usually reveals the true scale of proficiency. |

|

An absolute bonus is that this model sports a Portescap motor and gearbox. By the looks of it it seems to have been run, but then again I can hardly imagine this loco ever ran well. Note the cusps on the etched frame plates. A clear sign of a inexperienced builder. |

|

And there is the ultimate proof: the frames have been glued as well. So my final verdict is that this loco will need to be completely disassembled. If a builder does not trust himself to solder the frames, I do not trust him to build the frames square and true. |

|

The underside also reveals the poor quality of the paint job. |

|

As do the wheel rims |

|

The number plate was painted red, but not sanded to reveal the brass lettering. Note that not even the etch notch at the right hand side has been file round. |

|

Well, the glue was not strong enough to hold the front unit attached to the boiler cradle. By the looks of it several repair attempts have been made. |

|

Comparison to the NSWGR AD60 |

|

| I could not resist taking my AD60 out of its display and make a comparison in size. | |

|

|

|

|

|

Click on the photo to enlarge |

|

Sign my

GuestBook